soy wax manufacturing process

High-quality soy wax flakesScented candles have become a popular choice for creating a soothing ambiance and enhancing relaxation. Among the various candle options available, soy candles stand out for their eco-friendly nature and clean-burning properties. If you’re passionate about candle manufacturing, this comprehensive guide is for you.

We’ll walk you through the process step by step, while also shedding light on essential regulations and testing procedures. Understanding these aspects, ensure that candle-making adheres to industry standards and produces exceptional products.

How to manufacture Soy Candles?

Crafting soy candles is a delightful and creative process that allows you to personalize scents, colors, and designs. Here’s an organized breakdown of the key steps involved:

- Step 1: Gather Your Materials

- Step 2: Prepare the Soy Wax

- Step 3: Add Fragrance and Color

- Step 4: Prepare and Insert the Wick

- Step 5: Pour the Wax

- Step 6: Trim the Wick

Step 1: Gather Your Materials

To create beautiful soy candles, gather the following materials:

High-quality soy wax flakes: Opt for 100% soy wax flakes for optimal results.

Candle wicks: Choose wicks specifically designed for soy wax candles, ensuring they fit your container size.

Fragrance oils: Select high-quality fragrance oils formulated for candle making, keeping in mind the desired scent intensity.

Candle dye: Use candle-specific dyes to achieve vibrant and consistent colors.

Heat-resistant containers: Consider using mason jars, tins, or glass containers that complement your desired aesthetic.

Thermometer, pouring pot, and stirring utensils: These tools are essential for temperature control and smooth pouring.

Step 2: Prepare the Soy Wax

Follow these sub-steps to prepare the soy wax for your candles:

Measure the required amount of soy wax flakes based on your container’s volume.

Melt the wax in a pouring pot using a double boiler or microwave, following the manufacturer’s instructions.

Monitor the temperature closely, ensuring it reaches the recommended melting point (around 160-180°F or 71-82°C).

Step 3: Add Fragrance and Color

Enhance your candles with delightful scents and colors by following these sub-steps:

Remove the melted wax from the heat source and allow it to cool slightly.

Add fragrance oil to the wax according to the recommended ratio (typically 6-10% of the wax weight).

If desired, add a few drops of candle dye and mix thoroughly to achieve your desired color.

Step 4: Prepare and Insert the Wick

Properly prepare the wick for optimal burning performance:

Attach the wick to the center of the container using a wick sticker or hot glue.

Straighten the wick and ensure it remains centered.

Step 5: Pour the Wax

Pour the scented and colored wax into the container while taking care not to disturb the wick:

Leave a small gap at the top to allow for any necessary adjustments later.

Allow the candles to cool and solidify completely, typically for a few hours or overnight.

Step 6: Trim the Wick

Complete your soy candles by following these final sub-steps:

Once the candles have fully hardened, trim the wick to approximately ¼ inch (6 mm) for optimal burning performance.

The soy candles are now ready to infuse any space with delightful fragrance and gentle illumination.

Candle Regulations and Testing

Understanding the regulations and testing requirements is crucial when venturing into the candle-making business. Here’s an organized overview of the key considerations:

Safety Standards:

Familiarize yourself with the safety standards and regulations governing candle manufacturing in your region.

Ensure the production methods, materials, and labeling meet the required standards to protect consumers.

Testing Procedures:

Regular testing is essential to assess the quality, performance, and safety of your candles:

Conduct burn performance tests to evaluate factors like burn time, flame height, and soot production.

Assess fragrance throw to determine the scent’s intensity and longevity.

Test wick stability to ensure it remains centered and doesn’t create excessive smoke.

Check packaging integrity to guarantee proper sealing and protection.

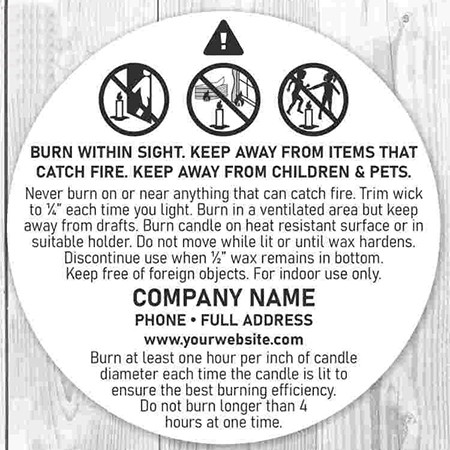

Labeling Requirements:

Proper labeling is vital to provide essential information to consumers and comply with regulations:

Clearly label your candles with information such as the fragrance used, burning instructions, and safety warnings.

Comply with any mandatory labeling requirements in your region, including allergen information and flammability warnings.

Product Liability Insurance:

Consider obtaining product liability insurance to safeguard your business against potential claims arising from product defects or accidents.

This guide has provided you with the knowledge and steps necessary to embark on a successful journey of making soy candles. By following the crafting process and understanding the significance of candle regulations and testing, to create high-quality candles that meet industry standards and delight your customers.