Effective Collaboration with Your Cosmetic Supplier: From Design to Delivery

Collaborating effectively with your cosmetic supplier is key to ensuring a successful partnership and delivering high-quality products. In this article, we will guide you through essential steps and considerations to streamline communication and optimize your collaboration. From graphic design and copywriting work to product proofing and confirmation, as well as the procurement process, we’ll explore how to effectively work with your supplier at every stage.

- Graphic Design

- Copywriting Work

- Product Proofing and Confirmation

- Procurement Process

Graphic Design:

Graphic design plays a vital role in the overall presentation of cosmetic products. Depending on the arrangement, either the brand owner or the processing factory is responsible for the design work.

If the brand owner leads the design process, they should provide the factory with essential product information (ingredients, usage, precautions, etc.) and factory details (name, address, standards, license number, barcode, etc.).

Conversely, if the factory handles the design, the brand owner must supply a complete Visual Identity (VI) package, including the brand’s logo, main colors, character, and style requirements. Prompt and efficient communication is crucial during this phase to ensure quick decision-making.

Copywriting Work:

Copywriting encompasses product descriptions, promotional content, and marketing materials. Typically, the cosmetic manufacturer handles product copywriting, while other aspects of copywriting are agreed upon by both parties.

Product Proofing and Confirmation:

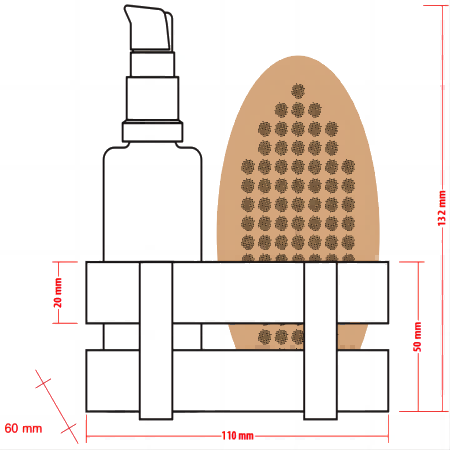

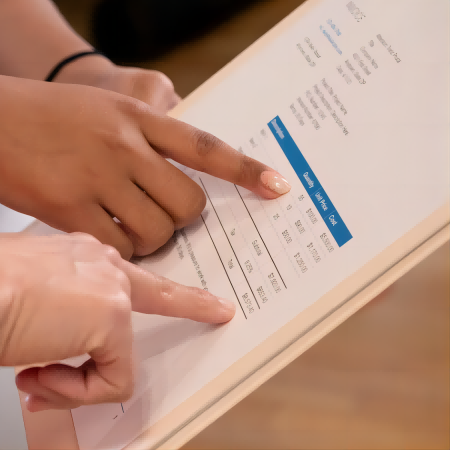

Certain aspects of product proofing and confirmation may be completed before signing the contract. If any steps are pending, the cosmetics OEM manufacturer’s business department should promptly arrange for them to be completed after contract signing. Detailed proofing requirements should include product name, color, function, state, fragrance, and any special requests. It’s crucial to provide samples to the brand owner for review, who may request modifications or additional tests until they are satisfied. Samples should be retained for further reference and quality checks.

Procurement Process:

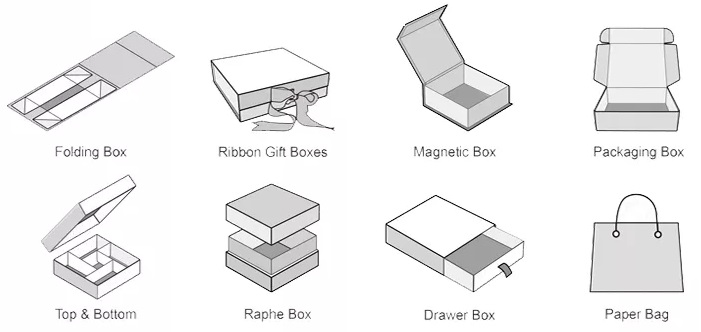

Once the factory has conducted standard stability testing and obtained approval from the brand owner regarding the samples, the procurement process begins. The cosmetics processor takes charge of purchasing, with special emphasis on proofing to avoid any mistakes during printing or packaging. Color accuracy is particularly important, as variations can occur between the design draft and the final product. It is advisable for the factory to adopt a proactive approach by predicting potential losses and ensuring sufficient quantity by incorporating an overflow margin. Quality inspections upon the arrival of packaging materials help identify any discrepancies between samples and bulk goods, allowing for timely notification and corrective action by the procurement or business processing team.

Effectively collaborating with your cosmetic supplier is essential for a successful partnership. By focusing on graphic design, copywriting work, product proofing and confirmation, and the procurement process, you can optimize communication, reduce errors, and enhance overall efficiency. Remember to foster open lines of communication, define expectations clearly, utilize visual references, maintain regular progress updates, and provide timely feedback. With these strategies in place, you’ll pave the way for a fruitful collaboration that delivers exceptional cosmetic products to your customers.