how does factory make melt & pour soap?

When we make DIY handmade soap, we find it fun and interesting. But do you know how soap is produced in the factory? Let us take a look how does factory make melt & pour soap.

- Soap Base Selection

- Melting the Soap Base

- Mixing

- Pouring & Molding

- Cooling

- Demolding and Cutting

- Packaging and Quality Assurance

Soap Base Selection:

The first step in melt-and-pour soap production is selecting a high-quality soap base. Source soap bases that are free from harmful chemicals and gentle on the skin. This step forms the foundation for the creative journey that follows.

Melting the Soap Base:

The chosen soap base is gently heated until it reaches the ideal melting point. Specialized equipment is used to ensure a controlled and precise melting process. This step is crucial for maintaining the integrity of the ingredients and preserving the desired properties of the soap.

Mixing:

Once melted, transfer the soap base to the mixing tanks. Blend a wide range of natural ingredients into the melted soap base, such as essential oils, botanical extracts, colorants, fragrances, and other desired ingredients can be added according to your recipe.

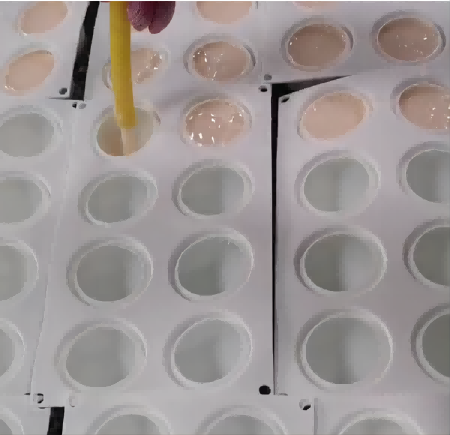

Pouring & Molding:

After the soap base is infused with the desired ingredients, carefully pour the prepared soap mixture into pre-arranged molds. There are a lot of shapes and sizes available.

Cooling: Transfer the filled molds onto a cooling conveyor belt. This belt allows the soap to solidify at a controlled rate, ensuring proper setting and a smooth finish.

Demolding and Cutting: Once the soap has solidified completely, remove it from the molds. Utilize cutting machinery to precisely cut the soap base into uniform bars.

Packaging and Quality Assurance: The final step involves packaging the individual soap bars. This can involve wrapping them in labeled paper or placing them in pre-designed boxes, depending on your brand and marketing strategy. Quality control measures throughout the process to ensure consistent product quality. This includes monitoring temperatures, weighing ingredients precisely, and inspecting the final product for any defects.

The large-scale production of melt-pour soap provides an efficient method of producing large quantities of customized soap to meet market demand.This approach allows for the customization of colors, fragrances, and ingredients, allowing you to develop a unique brand identity for your soap products.